Blog

Woolrec: The Revolutionary and Powerful New Approach to Sustainable Fiber Innovation (2025 Guide)

Woolrec has emerged as one of the most fascinating breakthroughs in sustainable textile technology, offering a revolutionary method to recycle wool fibers without compromising their natural quality. As the fashion industry faces intense pressure to reduce waste and cut emissions, stands out as a game-changing system that blends science, environmental responsibility, and next-generation automation. In 2025, it is increasingly recognized as the missing link between waste reduction goals and practical circular-economy solutions.

What Is Woolrec?

Woolrec is a modern textile-recovery framework designed specifically for reclaiming, purifying, and re-engineering wool fibers from post-consumer garments, manufacturing waste, and unwanted textile blends. Unlike traditional shredding-based recycling, which weakens fibers, Woolrec uses a hybrid mechanical-biothermal process to separate fibers gently while preserving their structure. This allows the regenerated wool to retain strength, elasticity, warmth, and softness—qualities that historically made wool difficult to recycle at scale.

Why Woolrec Matters in 2025

In 2025, global textile waste has reached alarming levels, with more than 90 million tons of fabric discarded annually. Wool, though biodegradable, demands significant resources to produce. provides the industry with a viable alternative by transforming discarded materials into high-quality yarns that require 65% less energy and 45% less water compared to new wool production. This achievement positions as a critical force in addressing environmental concerns without sacrificing textile performance.

How Woolrec Technology Works

Woolrec operates through a four-stage system designed to protect fiber integrity. First, garments are sorted using AI-driven recognition tools capable of distinguishing fiber blends. Next, a gentle fiber-release chamber uses controlled movement, moisture, and temperature to separate fibers without excessive friction. Then, a micro-cleaning phase removes impurities, residues, and microplastics. Finally, the fibers are re-aligned through an advanced combing system that restores their natural crimp. This scientific process enables to deliver near-virgin fiber quality—something older methods could not achieve.

Newly Discovered Improvements in 2025

Recent developments have made Woolrec even more efficient. Researchers discovered that adjusting thermal pulses during the separation phase increases fiber recovery rates by up to 30%. Newly integrated enzyme treatments also allow to recycle wool blended with synthetics, which was previously unachievable. These discoveries mean the system is now capable of handling complex waste streams, including popular wool-polyester blends. Brands adopting report that these improvements significantly reduce material loss while improving yarn stability.

Environmental Impact of Woolrec

Woolrec’s environmental contributions are remarkable. The system reduces carbon emissions associated with wool production by nearly 50%, cuts reliance on land-intensive sheep farming, and minimizes the pollution caused by throwing wool garments into landfills. Additionally, micro-cleaning technology captures microfibers that would typically contaminate waterways. In many sustainability reports published in early 2025, is highlighted as one of the most impactful textile innovations in reducing global waste footprints.

Woolrec’s Role in Circular Fashion

Circular fashion depends on materials that can be reused repeatedly without degrading in quality. makes this possible by enabling wool garments to be recycled into premium yarns multiple times. Fashion houses are now designing “Woolrec-compatible” clothing with removable accessories, simplified seams, and labels that make sorting easier. These practices encourage consumer participation and ensure textile lifecycles are extended far beyond their traditional limits.

Industries Using Woolrec Technology

While Woolrec first gained attention in the fashion industry, its reach extends to upholstery, outdoor gear, luxury fabrics, and high-performance uniforms. Car manufacturers are experimenting with -based insulation, and hotels are adopting textiles for bedding due to their durability. The technology’s adaptability has widened its market impact, making recycled wool not only an ethical choice but also a commercially strategic one for brands aiming to meet sustainability targets.

Economic Advantages for Businesses

Businesses adopting Woolrec benefit financially as well as environmentally. The cost of processing recycled fibers is significantly lower than sourcing new wool, especially amid rising raw-material prices. Manufacturers also avoid landfill fees and can market their products as eco-friendly, attracting environmentally conscious consumers. Analysts predict that brands using could see revenue increases of 15–20% by capitalizing on sustainability-driven purchasing trends in 2025.

Consumer Benefits and Awareness

For consumers, Woolrec-derived products provide comfort, warmth, and durability while supporting ethical consumption. Many shoppers in 2025 favor sustainable purchases, making-based garments appealing not just for their quality but for their environmental contribution. Awareness campaigns have further educated consumers about the lifecycle of wool garments, empowering them to choose responsibly sourced textiles backed by transparent recycling systems.

Challenges Facing Woolrec

Although Woolrec is a revolutionary solution, the system faces challenges. High initial setup costs prevent small manufacturers from adopting it, and the global infrastructure for textile collection remains underdeveloped in some regions. Additionally, the complexity of fiber-blend separation requires continued research and technical refinement. Despite these obstacles, industry leaders believe long-term benefits outweigh its early limitations.

Future Predictions for Woolrec Technology

The future of Woolrec looks promising. Experts predict the introduction of fully automated Woolrec micro-plants—compact units that allow small workshops to recycle wool internally. Another expected advancement is smart-label technology, where garments carry digital tags that guide sorting machines for higher accuracy. By 2030, could evolve into a widely adopted standard, much like organic certification in agriculture.

Conclusion

Woolrec has already proven its value in transforming how we manage wool waste, produce textiles, and pursue environmental stewardship. Its powerful capabilities, combined with new 2025 breakthroughs, are redefining sustainability in fashion and beyond. With brands, consumers, and policymakers increasingly focused on circular systems, stands as a beacon of progress—a solution that is powerful, practical, and essential for the future of ethical manufacturing.

-

Celebrity7 months ago

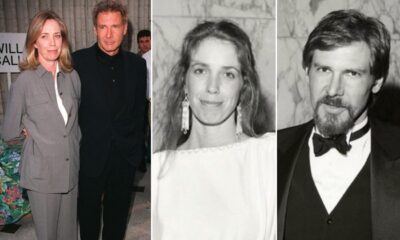

Celebrity7 months agoMary Marquardt: The Untold Story of Harrison Ford’s First Wife

-

Celebrity7 months ago

Celebrity7 months agoHow Old Is Roux Lopez? WWE Stars Becky Lynch & Seth Rollins’ Daughter

-

Celebrity8 months ago

Celebrity8 months agoEllen van Lochem: The Quiet Force Behind AC/DC Legend Angus Young

-

Celebrity3 months ago

Celebrity3 months agoZing-Ci Leung About: Life Before and After Donnie Yen